Stainless Steel | Alloy Steel | Duplex Steel | Super Duplex | Carbon Steel | Monel | Nickle Alloys | Inconel | Incoloy | Hastelloy | Galvanized Steel | Titanium | Tool Steel | Hot Rolled Steel | Cold Rolled Steel | Aluminium | Copper | Bronze

Cold Rolled Steel

Learn the benefits of each type of steel, and which to pick for your project

Steel comes in many grades, specifications, shapes, and finishes—the World Steel Association lists over 3,500 different grades of steel, each with unique properties. The various types mean that steel can by widely used in infrastructure, appliances, vehicles, wind turbines, and many more applications.

Optimizing steel’s properties for each application goes beyond changing the chemical composition, however. The manufacturing processing of steel can also have a significant impact on steel products—even when the grades and specifications are the same. One key distinction among pre-fabricated steel products is the difference between hot rolled and cold rolled steel.

What’s the difference between hot rolled and cold rolled steel?

It’s important to note that the main difference between hot rolled and cold rolled steel is one of process. “Hot rolling” refers to processing done with heat. “Cold rolling” refers to processes done at or near room temperature. Although these techniques affect overall performance and application, they should not be confused with formal specifications and grades of steel, which relate to metallurgical composition and performance ratings. Steels of different grades and specifications can be either hot rolled or cold rolled—including both basic carbon steels and other alloy steels.

It may seem obvious, but some types of steel are better suited for certain applications. Knowing which to use can help avoid over-spending on raw materials. It can also save time and money on additional processing. Understanding the differences between hot and cold steel is integral to choosing one over the other.

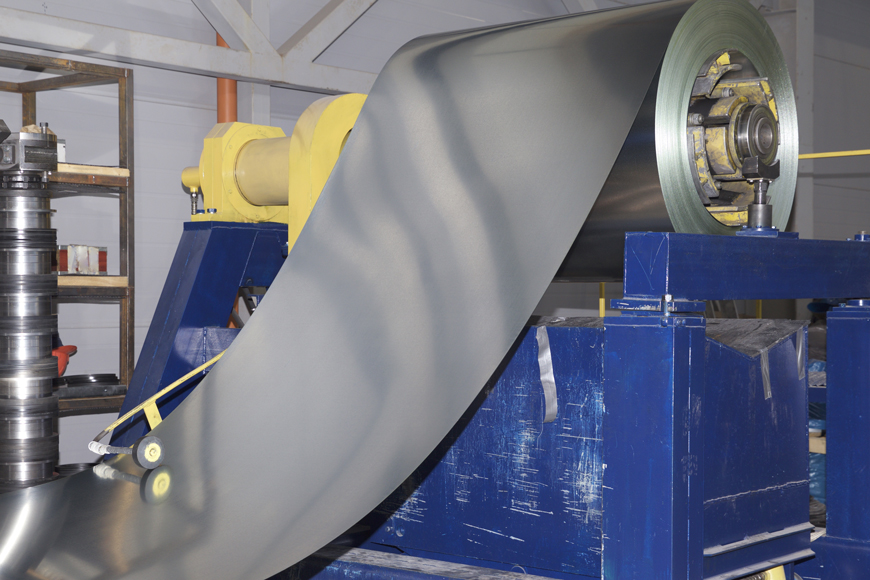

Cold rolled steel

Cold rolled steel is essentially hot rolled steel that has been through further processing. Once hot rolled steel has cooled, it is then re-rolled at room temperature to achieve more exact dimensions and better surface qualities.

Cold “rolled” steel is often used to describe a range of finishing processes, though technically “cold rolled” applies only to sheets that undergo compression between rollers. Steel forms that are pulled, such as bars or tubes, are “drawn,” not rolled. Other cold finishing processes include turning, grinding, and polishing—each of which is used to modify existing hot rolled stock into more refined products.

Cold rolled steel can often be identified by the following characteristics:

- Better, more finished surfaces with closer tolerances

- Smooth surfaces that are often oily to the touch

- Bars are true and square, and often have well-defined edges and corners

- Tubes have better concentric uniformity and straightness