Plug valves are valves with cylindrical or conically-tapered “plugs” which can be rotated inside the valve body to control flow through the valve. The plugs in plug valves have one or more hollow passageways going sideways through the plug, so that fluid can flow through the plug when the valve is open. Plug valves are simple and often economical.

When the plug is conically-tapered, the stem/handle is typically attached to the larger diameter end of the plug. Plug valves usually do not have bonnets but often have the end of the plug with the handle exposed or mostly exposed to the outside. In cases like that, there is usually not much of a stem. The stem and handle often come in one piece, often a simple, approximately L-shaped handle attached to the end of the plug. The other end of the plug is often exposed to the outside of the valve too, but with a mechanism which retains the plug in the body.

It is also possible for a plug valve to have more than two ports. In a 3-way plug valve, flow from one port could be directed to either the second or third port. A 3-way plug valve could also be designed to shift flow between ports 1 and 2, 2 and 3, or 1 and 3, and possibly even connect all three ports together. The flow-directing possibilities in multi-port plug valves are similar to the possibilities in corresponding multi-port ball valves or corresponding multi-port valves with a rotor. An additional possibility in plug valves is the have one port on one side of the plug valve and two ports on the other side, with two diagonal and parallel fluid pathways inside the plug. In this case the plug can be rotated 180° to connect the port on the one side to either of the two ports on the other side.

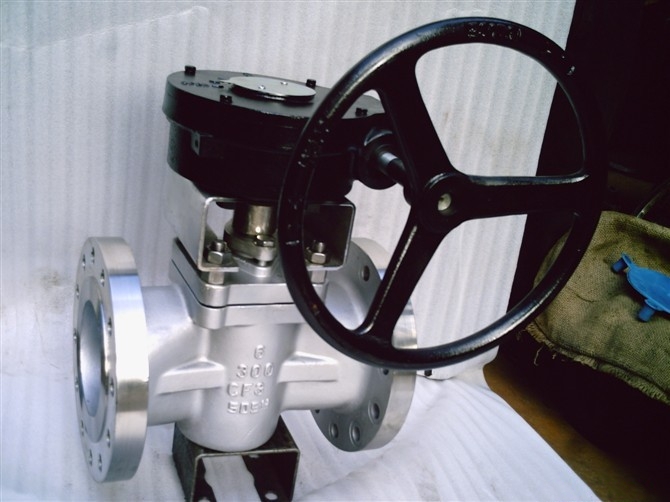

Super duplex plug valve

Duplex plug valves

Size: ½” up to 36“ (DN15 up to Dn900)

Pressure Rating: ASME 150# to 2500#

Materials: Carbon Steels, Low Temperature Carbon Steel, Martensitic Steels, Austenitic Stainless Steel, Duplex Stainless Steels, Super Duplex Stainless Steels, Nickel Alloys, Nickel Aluminum Bronze, Hastelloy, Inconnel, Titanium Alloy & Carbon Steel with Internal CorrosionResistant Alloy (CRA) Overlay

Design Standard: API6D, API 599, BS 5353, MESC SPE 77/107

Pressure / Temperature Rating: ASME B 16.34

Test (Inspection) Standard: API 598, API 6D, MESC 77/107, ISO 5208

Construction Details: Inverted Plug Pressure Balanced /Lubricated

End Connection: Screwed, Socket Weld, Flanged, Hub End, Butt-Weld

Operator / Actuator: Lever, Gear, Actuator (Pneumatic, Hydraulic, Electro-Hydraulic and Electric Motorised)

Plug Valves are available in three different types versions

• Full Bore

• Regular Bore

• Extended Stem Valves

Sleeved Plug Valve

Size:2~24″(DN50~DN600)

Rating:150~900LB (PN16~PN160)

Body Materials:Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel

End Connection: RF

Lubricated Plug Valve

Size:2~24″(DN50~DN600)

Rating:150~900LB (PN16~PN160)

Body Materials:Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel

End Connection: RF

Steam Jacket Plug Valve

Size:2~24″(DN50~DN600)

Size:2~24″(DN50~DN600)Rating:150~900LB (PN16~PN160)

Body Materials:Carbon Steel, Stainless Steel, Alloy Steel, Duplex Steel

End Connection: RF